Transitioning to

Green Material Sources.

Achieving the green transition means overcoming three challenges: finding the right feedstock, engineering the right processing technologies, and developing end markets at scale.

The issues

53.8

GT CO2e

Global GHG emissions reached 53.8 Gt CO2e in 2022.

+ 15 %

global GHG

Building materials, plastics, and packaging, metals and mining account for 15-20% of global GHG emissions.

3.5

billion tonnes

Global waste to landfills is set to increase unabated to more than 3.4 billion tonnes per year by 2050.

Navigating the green material transition, mitigating risks, and creating new opportunities.

As industries seek to reduce their environmental impact, the shift to sustainable, bio-based and recycled materials is essential. Manufacturers are at the heart of this transition, driving innovation in material science to replace traditional, resource-intensive, virgin inputs with renewable, biodegradable alternatives.

By embracing green materials and pathways, manufacturers can lower carbon footprints, reduce reliance on finite resources, and create more resilient and sustainable supply chains. This transition not only enhances environmental responsibility but also meets growing consumer demand for eco-friendly products, fostering long-term competitiveness and resilience through new markets creation. The manufacturing sector needs to lead the green material shift to achieve a sustainable, circular economy for the future.

Key Questions

- How fast are increasing and more strident regulations, consumer demands, and market competition threatening your core business?

- What is your “degree of risk” with incumbent materials? Which “green” materials would be promising candidates for “substitution” and why?

- How mature is the ecosystem of alternative materials available to you in terms of: technology, availability, performance, price, and supply-demand balance?

- When, where, and by how much will “green materials” cannibalize traditional virgin use of “synthetic” materials?

- How can you craft and pursue a regulatory resilient strategy for the future?

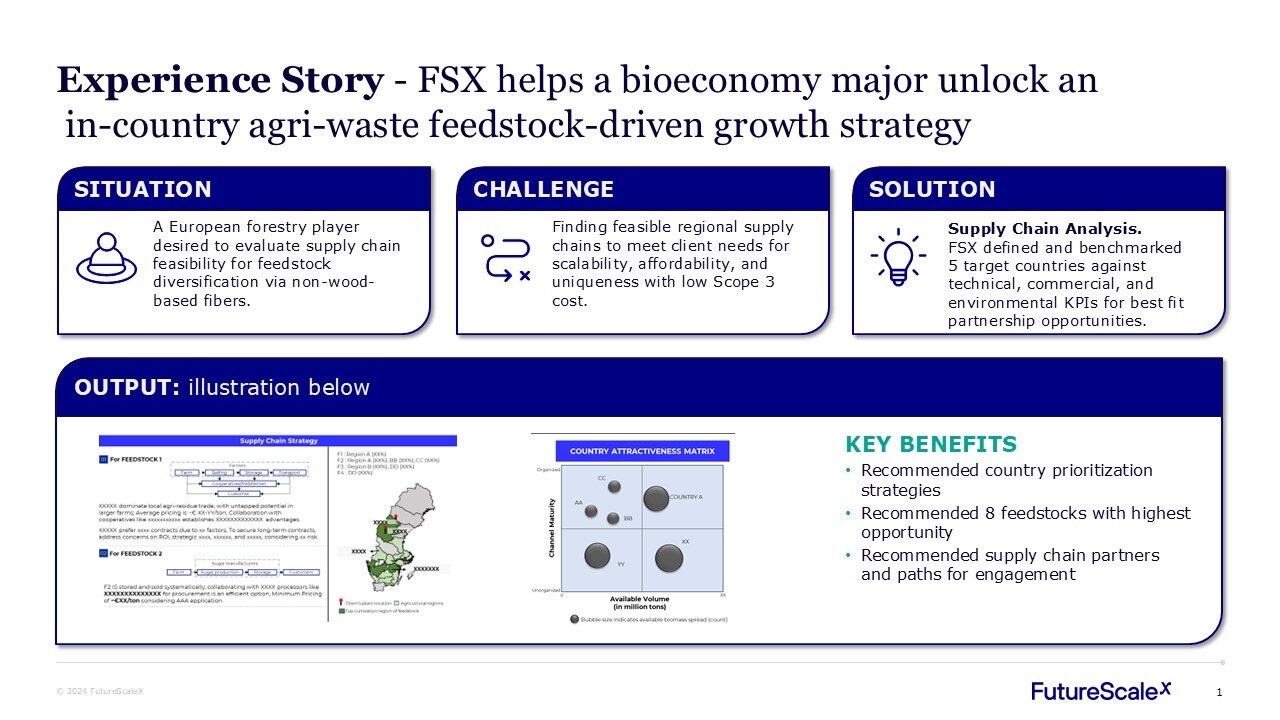

Related Case Study

Forestry Leader Diversifies Supply Chain Feedstock Sources

Helped a forestry industry leader build a new go-to-market and product line expansion strategy utilizing non-wood feedstock options and opportunities, driving regional expansion into the bioeconomy sector.

Forestry Leader Diversifies Supply Chain Feedstock Sources

Helped a forestry industry leader build a new go-to-market and product line expansion strategy utilizing non-wood feedstock options and opportunities, driving regional expansion into the bioeconomy sector.

How we help

Our expertise guides you in navigating the transition to sustainable materials, addressing regulatory impacts, market readiness, and the potential for green alternatives to replace traditional materials.

%20(1)%20(1).png?width=544&height=70&name=futurescalex-logo-full-colour-rgb-827px@72ppi%20(3)%20(1)%20(1).png)