Transforming Your Loop,

Creating Circular Value.

The challenge of circular is overcoming traditional linear thinking. New designs, new manufacturing, and new business models are needed. We help you put the pieces in place.

The issues

1.6

Earths

We consume 60% more resources than the Earth can renew each year, potentially needing three Earths' worth by 2050.

+ 2 bn

tonnes of waste

The world discards over 2 Bn tonnes of resources, projected to increase to 3.4 Bn tonnes by 2050.

45 %

of emissions

Nearly half of all emissions originate from the production of cars, clothes, food, and other products.

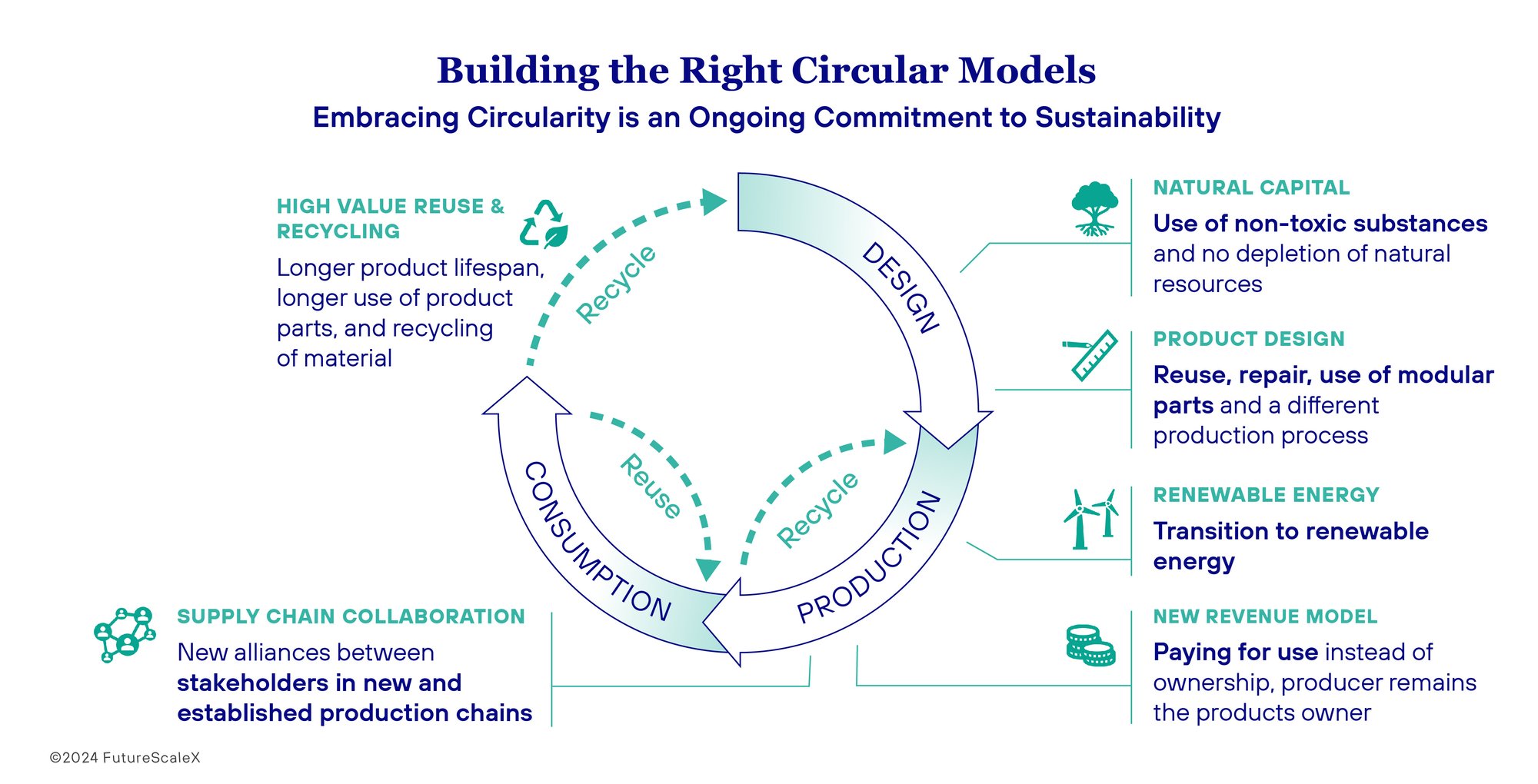

Embracing and implementing a Circular Business Model is an ongoing commitment to sustainability.

Manufacturing has long been the backbone of global economies, and now it plays a critical role in pioneering the shift to circular economies by harnessing new technologies and business models. In this new paradigm, the sector is uniquely positioned to transform how products are designed, produced, repurposed, reused, and recycled, reducing waste and extending the lifecycle of resources.

By adopting circular principles, manufacturers optimize material efficiency, minimize environmental impact, and create new value streams through recycling, remanufacturing, and sustainable sourcing. This shift not only meets growing regulatory and consumer demands for sustainability but also drives innovation and competitiveness. Embracing circularity within the manufacturing sector fosters a more resilient, resource-efficient economy, ensuring long-term profitability and environmental stewardship for future generations.

Key Questions

- What resources are lost or wasted in your existing value chains?

- How can you best recover and reuse to improve both topline and bottom-line?

- What technologies, partners, and innovative business models are key to your success in implementing circular practices?

Related Case Study

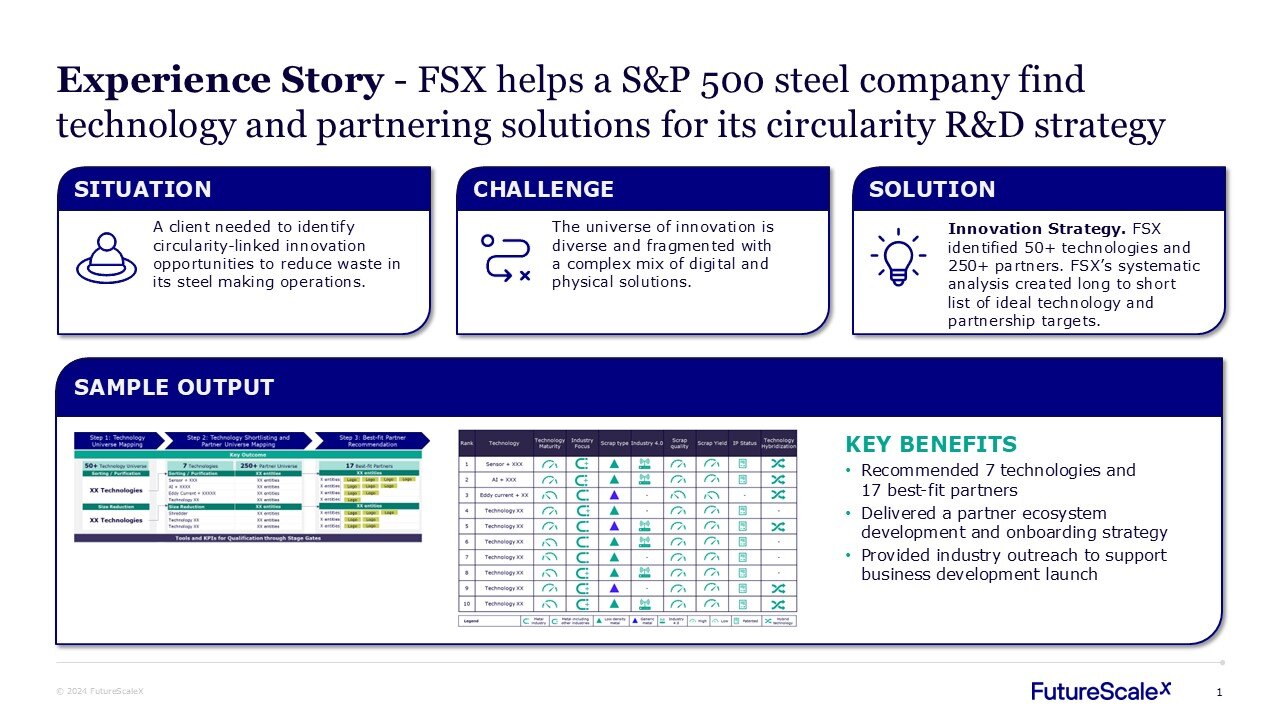

S&P 500 Steel Company Explores Opportunities in Circular Economy

Assisted an S&P 500 steel company to deploy circular economy opportunities by exploring digital and physical technology combinations to create novel advanced scrap sorting technology combinations and evaluating 250+ prospective technology partners.

S&P 500 Steel Company Explores Opportunities in Circular Economy

Assisted an S&P 500 steel company to deploy circular economy opportunities by exploring digital and physical technology combinations to create novel advanced scrap sorting technology combinations and evaluating 250+ prospective technology partners.

How we help

Our advanced research platform enables you to identify the best solutions for transitioning to circular economy. With integrated tools, you can evaluate resource options, assess lifecycle impacts, explore waste reduction strategies, and uncover new business models that align with circular principles.

%20(1)%20(1).png?width=544&height=70&name=futurescalex-logo-full-colour-rgb-827px@72ppi%20(3)%20(1)%20(1).png)